Electronic safety switching devices ES-2x Series

TÜV-certified, type-tested electronic safety switch for pressure limiting (SIL2)

pressure cut out | Pressure switch | Safety Pressure limiter | Pressure regulator

- Monitoring of up to four pressure circuits

- Simple and precise setting of switching thresholds, reset values and delay times

- Robust, industrial-suited and fail-safe design

- Integrated self-test functions

- Measured value and alarm indication on the display

- Comprehensive service functions, as well as data logging

- On-site operation on the unit and via smartphone

ES-2x Series

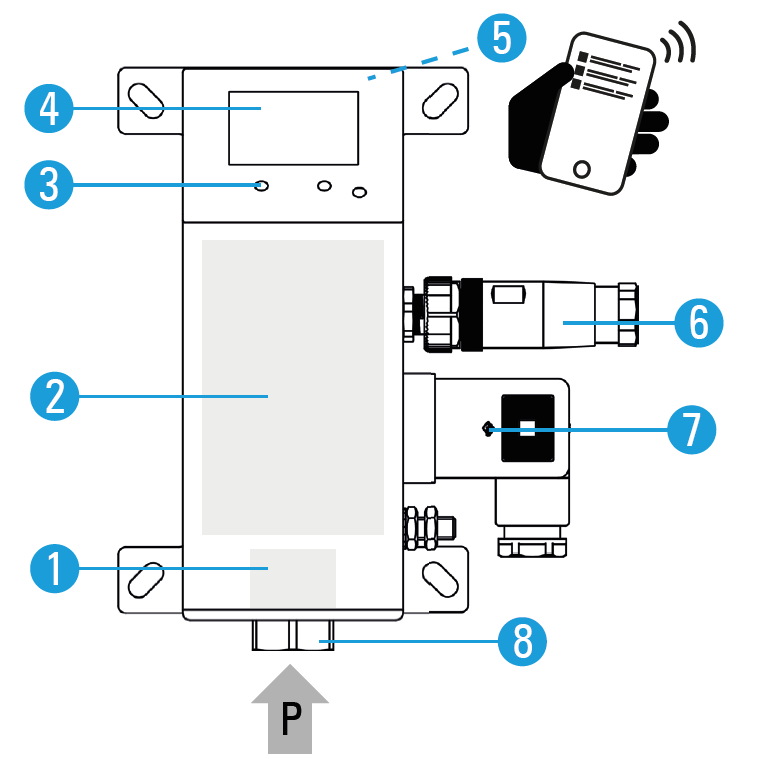

The devices of the ES-2x series are electronic safety switching devices for pressure monitoring with comprehensive self-diagnosis functions and fail-safe design. The devices are used as pressure regulators, for minimum or maximum pressure limitation on compressors in cooling and air-conditioning systems, on heat pumps, steam boiler systems and on hydraulic systems.

With the exception of the integrated switching relays, there are no mechanically moving components, resulting in high vibration resistance and a long service life. The switching limits can be conveniently set and precisely monitored. Comprehensive self-diagnostic and logging functions ensure safe monitoring and fast shutdown of the source of danger as well as high traceability of events that have occurred.

All units delivered as pressure monitors, pressure limiters or safety pressure limiters (also combined) are EU type-tested safety switching devices for pressure limitation.

Designed for maximum safety and ease of use |

|

|

|

Dokumente und Downloads

General information ES-2x series

mounting and installation instructions ES-2x Series (tba)

Quick Start Guide ES-2x Serie (tba)

certificate of conformity (folgt)

TÜV certificate (folgt)

Pressure regulator

The reaction of the unit to pressure changes can be freely defined by entering parameters, e.g. two-point controller, PID controller, etc. Further functions can be added at the customer's request.

Pressure switch (PSH, DWK)

Setting of a switching point and a reset point (hysteresis).

The unit is automatically reset or unlocked.

Pressure limiter (PZH, DBK)

Setting of a switching point.

Resetting and unlocking is done manually on the unit (without tools).

Safety pressure cut out (PZHH, SDBK)

Setting of a switching point.

Resetting and unlocking is done manually with a tool directly on the unit.

System Design

General information

The ES-2... units are constructed from a compact, anodised aluminium housing and, depending on the unit variant, are designed as pressure regulators, pressure limiters, pressure monitors or safety pressure limiters of special design. Combinations, such as series-connected pressure limiters and safety pressure limiters according to EN 378, are also implemented in one housing.

The units are delivered with preset limit values and parameters. By setting a password, the device is virtually "sealed". After release (password entry), authorised persons can change the device settings and carry out manual tests on the device or via the app.

Pressure measuring cells

Monolithic pressure measuring cells made of stainless steel are used for monitoring relative pressures. Since there are no sealing rings or weld seams, the devices of the ES-2... series offer a high degree of robustness and media compatibility, even with aggressive media. Regardless of the relative or differential pressure measurement, the fault-free function of the pressure measurement is checked and documented by the device itself during operation.

Switching outputs

The units have two independent switching outputs, which are connected to a self-monitoring switching output in the unit versions ES-21 and ES-22. The installed relays are permanently monitored by an additional circuit. Sophisticated circuitry reliably prevents opening failure. In addition, the switching function is independently checked by the unit both when the power supply is applied to the unit and at regular intervals during operation. For this purpose, it is not necessary to switch off the consumers connected behind it. In the event of a fault, the unit always switches to the safe state.

measurement channel extension

Depending on the application, it may be necessary to use several pressure monitors for several pressure circuits. In this case, an ES-2x unit can be equipped with a channel extension. For this purpose, specially developed SIL-2-capable pressure transmitters (ZT-S...) are connected to the ES unit via a safe communication interface. The ES unit

is able to monitor several pressure circuits and provides a collective alarm when one of the set limit values is reached.

Setting, logging and testing work the same way as with a single-channel unit.

Switching output extension

Besides additional measuring channels, further switching contacts are added by means of an extension unit (ESE). This makes it possible to set up a distributed safety chain, e.g. of several pressure transmitters and switching outputs.

Connector mounting

Device Variants

Design variants of the ES-2.. Series

| Feature | ES-21 | ES-22 | ES-20 | ESE |

| SIL2 (ATEX) | yes, all devices | |||

| Type examination according to the Pressure Equipment Directive | yes, all variants | |||

| Number of safty functions |

1 safety function factory preset (DWK or DBK) |

Two combined safety functions factory preset |

Two combined safety functions freely selectable; to be specified when ordering |

|

| Direction of action |

Rising (maximum) or falling (minimum) factory preset |

Rising (maximum) or falling (minimum) Combination maximum and minimum |

To be defined when ordering: Combination maximum and minimum | |

| optional measurement channel extension | no | with ZT-S pressure sensors | no | |

| optional switiching output extension | no | with ESE Extension box | ||

Technical Data

| Specifications | |

| Operating voltage | 16...32 V DC (max. 5,9 W) |

| Dimension | 150 x 60 x 42 mm (L x W x H) |

| Housing | Aluminum (anodised) |

| Protection class | IP65 |

| operating conditions | |

| pressure type |

relative pressure differential pressure |

| media temperature | -40…+125 °C |

| ambient temperature | -20…+65 °C |

| parts in contact with medium | stainless steel |

| process connection (Adapter on request) | |

| version relative pressure | G ¼“ internal thread |

| version differential pressure | G 1⁄8“ internal thread |

| electrical connection | |

| Analogue current output | 1 x 4…20 mA |

| Digital Input / Output | Configurable as 2 x alarm or 1 x alarm and 1 x Remote unlocking |

| Load capacity of the switching contacts | |

| DC1: 16 A (24 V) DC13: 1,5 A (24 V) |

AC1: 16 A AC3: 10 A AC15: 7 A |

Measurement ranges

| Merkmal | Relativdruck | Differenzdruck |

| Measuring range (nominal pressure) |

-1…500 bar variable selectable |

0…1 mbar 0…10 mbar 0…50 mbar 0…100 mbar 0…250 mbar 0…1.000 mbar |

| Overload pressure | 2 x Nominal pressure | 10 x nominal pressure |

| Bursting pressure | 4 x nominal pressure | 15 x nominal pressure |

| Setting accuracy | 0,1 % of nominal pressure | |

| ... Further measuring ranges on request | ||

Functions

Wireless communication with Smartphone

The convenient setting of limit values, delay times and a configuration of the inputs and outputs is easily possible with the smartphone. In addition, various devices of the ES series can be managed and their device profiles saved. Manual device tests (e.g. switching of relays) can be carried out without applying pressure.

Provision and download of setting and test protocols

The units are preset at the factory. In addition, they carry out regular self-diagnosis independently. The setting log, all test results, alarms and device changes can be called up via the app.

Integrated Datenlogger

The ES units function as data loggers with internal device memory and timer. In addition to the process pressure, the temperature at the process connection is also recorded. Depending on the application, the measuring time, interval or continuous measurement is set.

Leak testing of machines and plants

When commissioning a plant, the devices of the ES series are also used for leak testing due to their precise measuring characteristics. For this purpose, the pressure drop and the temperature conditions at the process connection are determined and documented over an adjustable test time. The leak test protocol is stored in the device and read out via smartphone.

read out.

Fields of Application

- Refrigeration systems and heat pumps

- Ventilation, heating and air-conditioning technology

- Filter and pump monitoring

- Hot water and steam boiler monitoring

- Process measurement technology

- Mechanical and plant engineering