- Written by ZILA GmbH

- font size decrease font size increase font size

New sensor solution: Oil quality measurement in CHPs

In many machines and plants, oil is a fundamental component for reducing friction and preventing overheating. However, the quality of this fluid decreases over time due to oxidation, dilution and the consumption of additives. To prevent damage and extend a machine's service life, oil must be changed regularly. So far, this has required a fixed exchange interval or an extensive examination in a lab.

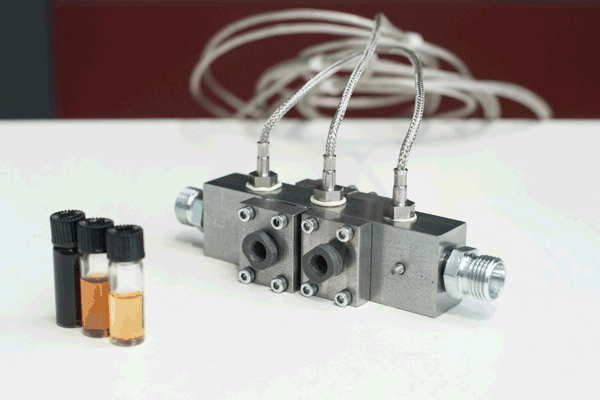

Oil flows into the sensor's measuring cell through two modules and is penetrated by infrared light. Various sensor elements then capture the light and evaluate the eight different spectral bands. How clearly oil can age is shown by the samples in the vials above: The one on the right contains new oil, the one on the left contains aged oil. (Photo: Oliver Dietze)

ZILA GmbH, a specialist in innovative sensor technologies, based in Suhl (Thuringia), has been collaborating with Professor Andreas Schütze and his team of researchers from Saarland University and other business partners, to develop a new type of sensor that permanently measures the oil quality in combined heat and power plants during operation. The sensor is equipped with a small measuring cell that reliably assesses the oil's chemical condition and warns the user when the quality deteriorates. Since the oil condition can now be read off at any time, oil exchanges can be anticipated and the fixed, regular exchanges become scheduled, needs-based maintenance operations in the long term, protecting the environment whilst increasing economic efficiency of systems and plants.

CHPs independently generate electricity and heat with a high level of efficiency for on-site consumption. However, operating costs increase if fixed oil exchange intervals are necessary. Professor Andreas Schütze explains:

In CHPs, the intelligent sensor for oil condition measurement is installed directly in the engine to monitor the quality of the oil.

Other areas of application include wind turbines and industrial machinery. In addition, the sensor can also be used in mobile applications and for monitoring other liquids.

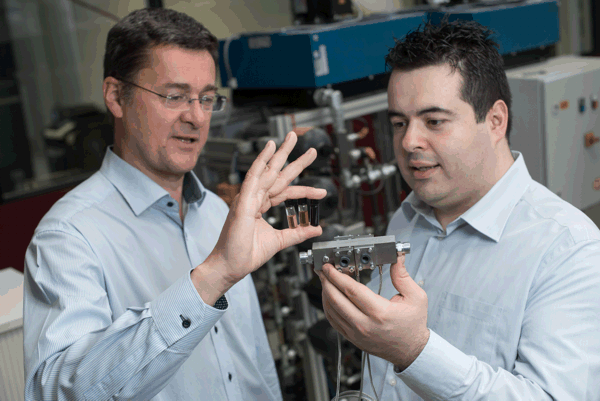

This new sensor solution will be presented at the Hannover Fair from 24 to 28 April at the Saarland research stand (hall 2, stand B46).

At the Hannover Messe, Prof. Andreas Schütze (left) and engineer Eliseo Pignanelli (right) will show a measuring system which constantly monitors the oil quality and predicts when an oil exchange is necessary. In this process, the oil flows through a measuring cell where it is penetrated by infrared radiation. The oil samples in the vials demonstrate how visibly oil can age: The one on the left contains new oil, the one on the right contains ages oil. (Photo: Oliver Dietze)

About ZILA GmbH

We, ZILA GmbH integrate innovative sensor technologies, develop and manufacture devices for measuring, testing and controlling gaseous and liquid media. We are known for our expertise and experience in the fields of pressure, climate, leakage and ventilation. With our innovative products and solutions, we would like to contribute to improving the quality of life, increasing energy efficiency and increasing personal and plant protection.

Related items

Latest from ZILA GmbH

- Information about change of company from ZILA to Fluid.iO

- FluidIX Lub-VDT: Inline sensor for condition monitoring of mechanical fluid characteristics

- ES-Series: Electronic safety switching devices with TÜV approval, SIL2 & EU type approval

- ZILA GmbH & RadonTec presenting ventilation control for comprehensive radon protection

- New product: Sensor for sulphur hexaflouride concentration measurement