- Written by ZILA GmbH

FluidIX Lub-VDT: Inline sensor for condition monitoring of mechanical fluid characteristics

The sensor is designed for use with mineral & synthetic oils and is therefore particularly suitable for inline oil analysis in predictive maintenance and servicing strategies.

Even at low flow rates, the LUB-VDT records the viscosity, temperature and mass density of the surrounding medium with high measuring accuracy. The precise and high-quality measurement data provided by the oil condition sensor is due to the unique measurement principle of the FluidIX Lub-VDT: a robust and reliable quartz crystal tuning fork resonator that achieves excellent data quality even under changing process conditions (pressure, temperature, flow) due to the high measurement rate.

Fluidix Inline Condition Monitoring Sensor

The screw-in sensor is easily and cost-effectively integrated into new machines and existing systems (retrofitting). This is ensured by the compact dimensions of just 95mm length and 30mm diameter as well as the standardised process connection. With these features, the oil condition sensor is ideally suited for mobile machinery as well as for industrial automation.

The measuring signals are evaluated via digital and analogue interfaces. In addition to two programmable 4...20mA signal outputs, ModbusRTU is also available.

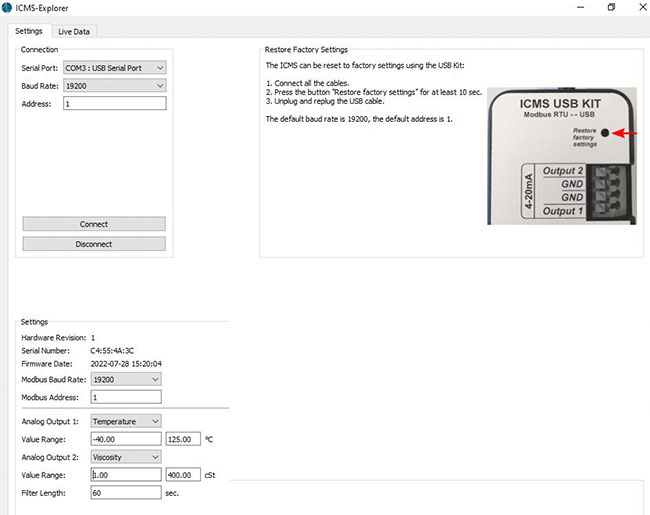

Configuration of the inline oil condition sensor with PC software

The sensor is configured with the USB kit and the corresponding PC software. The software also displays live measurement data. The connection from the sensor to the PC is made via a USB kit that converts the ModBus RTU signals to USB.