- Written by ZILA GmbH

DW500: Safety pressure limiter with switch function

DW500: Electronic safety pressure limiter with integrated pressure switch function

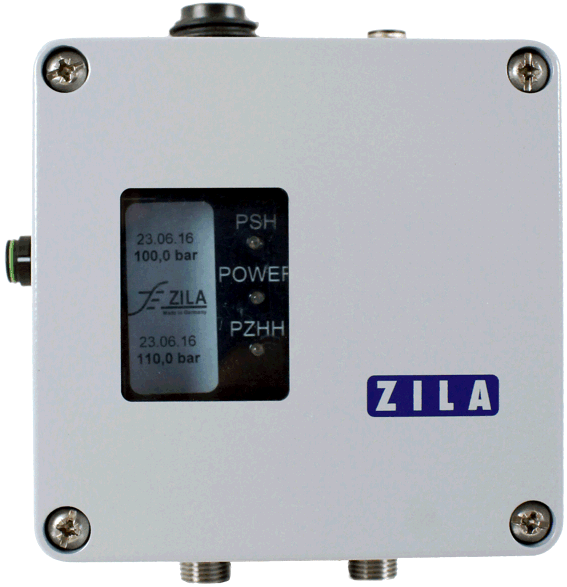

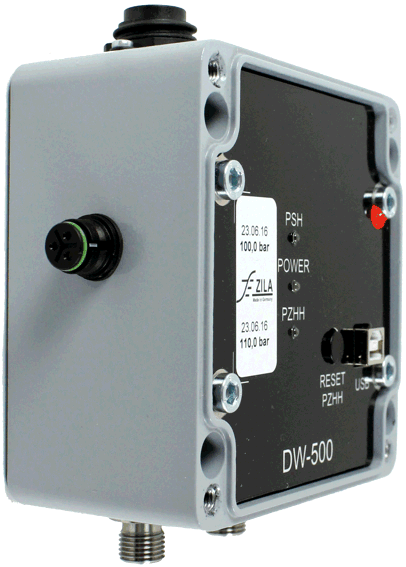

The safety pressure device DW500, which combines the functions of a pressure switch and a safety pressure limiter, is TÜV-certified and type-tested up to 500 bar. The DW500 is used for protection against exceeding the maximum operating pressure and falling below the minimum operating pressure in accordance with DGUV regulation 100-500 (BGR 500), chapter 2.35 (operator) and EN 378 (manufacturer). The safety pressure limiter and the pressure switch monitor the set pressure threshold and operate independently of each other in the encapsulated aluminium die-cast housing (IP 65).

Since any refrigerant of media group 1 and 2, according to the Pressure Equipment Directive 2014/68/EU, such as R744 (CO2), can be used with the electronic safety pressure limiter, it is an excellent device for use on compressors in refrigeration and air-conditioning systems, in heat pumps and steam boiler systems, as well as general hydraulic systems.

Adjustable hysteresis and remote unlocking

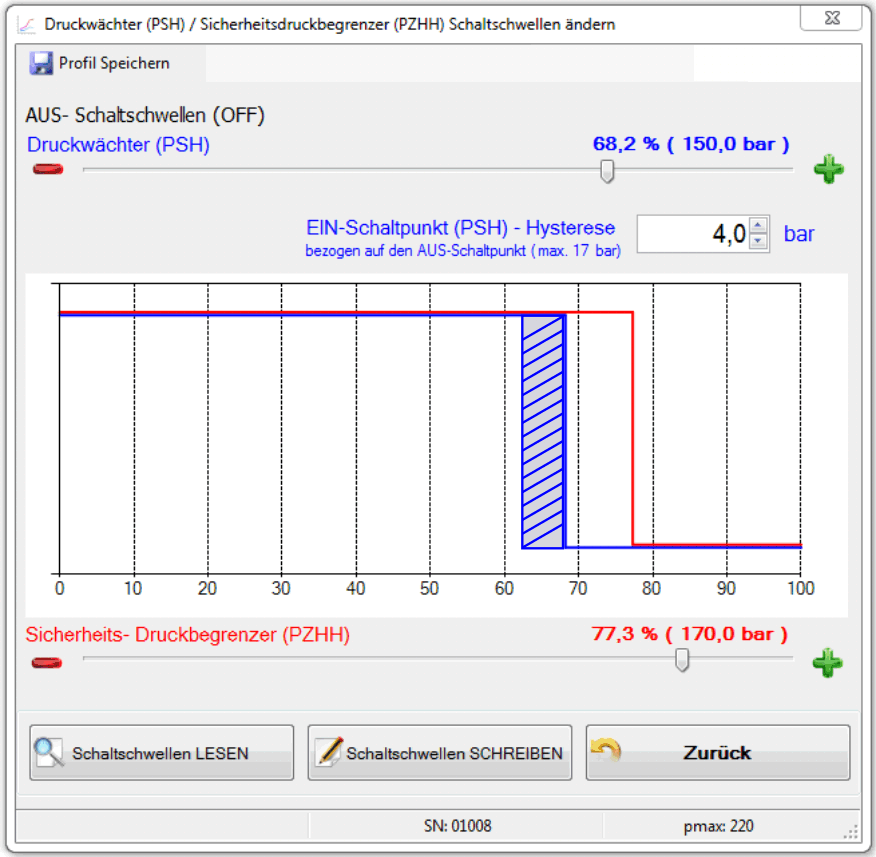

The greatest innovation of the DW500 unit is the electronically adjustable hysteresis, based on the set switching threshold. When the set switching threshold is reached, the pressure switch automatically unlocks again. The safety pressure limiter, in contrast, is reset manually or remotely. For remote unlocking, there is a three-pole flange socket on the side of the unit. Alternatively, an integrated button can be used for manual reset. The button can only be pressed after the housing cover has been removed. In addition, the DW500 has an independent, analogue 4-20 mA power supply for flexible integration into plants and systems. This means that an external pressure sensor is no longer required if the pressure of the system needs to be monitored or displayed continuously.

Parameter configuration

The safety pressure limiter DW500 is characterised by its high measuring accuracy and precisely adjustable switching points (accurate to 0.1 bar) and switching delays (in the range of 0-1 s with an accuracy of 0.1 s) via a PC software. Moreover, the switching relays can be function-tested. Since the switching points and the switching delays can be configured easily, systems and plants can be planned and used in the best possible way. The software-based testability also leads to significantly reduced commissioning and testing times. The device is certified by TÜV Rheinland, according to EC type examination (DGRL Directive 2014/68/EU), certificate no. 01 202 973-B-16-0023.

About ZILA GmbH

Safety, quality and efficiency for process and ventilation technology as well as in leak detection and testing. Gases, such as air, water vapour or CO2 and liquids, such as water and oil not only play a major role in everyday life, but also in industrial processes.

ZILA GmbH, based in Suhl, Germany, has been focusing on identifying the connections and gaining control of these media, while successfully offering a wide variety of product solutions on the market for more than 20 years. Our company integrates innovative sensor technologies and develops compact and intelligent devices for measuring, testing and controlling liquid and gaseous media. Besides standardised measuring, testing and control devices, we also design, develop and manufacture customised solutions.

Considering the rapidly changing technologies, standards and legal regulations, a close and continuous cooperation with our customers and partners has become part of our corporate philosophy.

Our experienced engineers and technicians will be pleased to help you find the best solution for your application.