- Written by ZILA GmbH

- font size decrease font size increase font size

Ready-to-use solutions for monitoring environmentally hazardous substances

The first application shows the autonomous control of minimum and maximum levels by the use of relays.

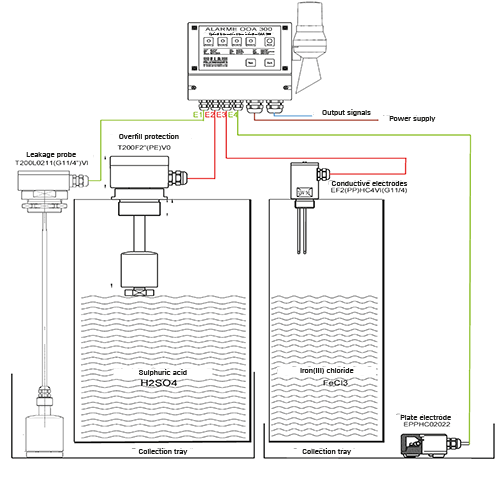

In the second application, we demonstrate the monitoring of sulfuric acid and ferric chloride III with leakage probes and overfill prevention devices in combination with a visual-acoustic alarm detector.

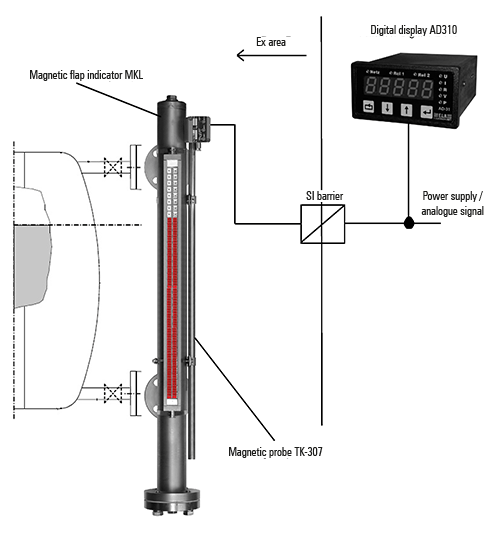

Level indication in hazardous areas presents special challenges for the technology. In our third example, we illustrate the monitoring of potentially explosive environments using a mechanical level indicator with magnetic flaps and a digital display.

Please find all information here as a separate PDF file:

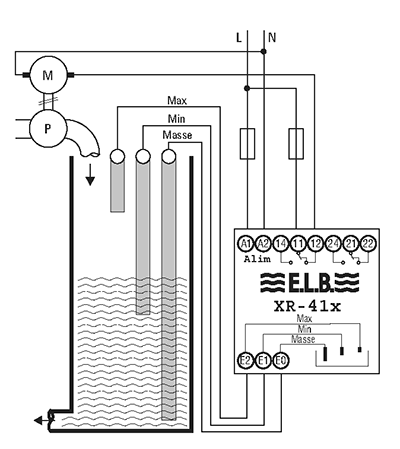

Stand-alone regulation of minimum and maximum filling levels

Mechanical level indicator with magnetic flaps for explosive environments

Stand-alone regulation of minimum and maximum filling levels

Conductive electrodes are applied to control and monitor the filling level of conductive liquids. For this reason, they are often used for min / max control, limit value signalling as well as for dry and overflow protection, combined with our electrode relays. The electrode relays XR-4xx have been developed for conductive level detection in the Ex area. Possible applications include all areas in which liquid, conductive media must be detected, controlled or regulated in any way. This can include both limit level detection (overflow / dry run) and minimum / maximum control systems.

Below you will find two examples for connection to check the filling level:

Example 1: Stand-alone system (without PLC) with relay 1 XR-41x // 1-channel relay

The probe consists of three electrodes:

- A grounding electrode for measuring the reference value

- One electrode for the minimum level

- One electrode for the maximum level

The relay XR-41x works as a stand-alone relay (no PLC is required here), which makes commissioning and maintenance of the system much easier.

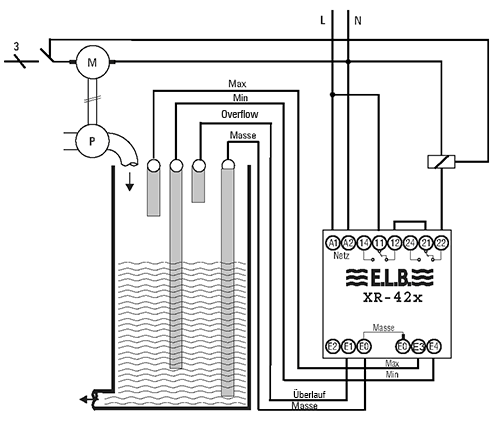

Example 2: Stand-alone system with relay XR-42x // 2-channel relay for overflow control

In this case, the probe has four electrodes each, the fourth being used together with the 2-channel relay XR-42x as a safety system with "overflow protection". Another function of the four electrodes is to use them as a "dry run" safety system.

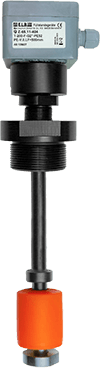

Environmental monitoring - monitoring sulphic Acid / Iron(III) Chloride with the alarm indicator OAA300

The level detectors T-20_.F... are approved as limit switches for overfill protection systems by the German Institute for Construction Engineering (DIBt) and are used for storing water-contaminating liquids. As soon as the level rises, the float switch activates the reed contacts installed in the guide tube through a magnetic system. Any change in resistance in the sensor circuit, triggered by switching, will then be evaluated by the system and the output relay will be activated. The wetted parts of the level sensors T-20_.F... are entirely made of PE, PP, PCV, PVDF. This makes the level sensors T-20_.F... ideal for use in tanks storing extremely aggressive media.

The leak detectors T-200.L are approved by the German Institute for Construction Engineering (DIBt) for detecting leaking, water-contaminating liquids in accordance with the regulation "WasBauPVO". This regulation determines the qualification of construction products and types under German Water Law. Our leak detectors T-200.L can be used for the following applications:

- As leakage sensors between a tank and its collection tray: The float of the leakage sensor is located on a stop ring below the set switching point and actuates the reed contacts in the guide tube with the mounted permanent magnets.

- Inside the float: If the float is pushed up by the rising liquid level, the reed contact switches and triggers the alarm.

The conductive electrode EF2 is approved for use as an overfill protection for water contaminating liquids by the German Institute for Construction Engineering (DIBt). Depending on the requirements, the EF2's screw connection and pipe are made of PE, PPH, PVC or PTFE. The electrode rods are made of stainless steel 1.4571, Hastelloy C, titanium or tantalum. This allows the conductive electrode to be used, even in very aggressive media.

The conductive plate electrode (model EP) for leakage detection is approved for monitoring collection chambers, retention tanks as well as inspection and filling shafts by the German Institute for Construction Engineering (DIBt). Depending on the requirements, the probe body is made of PE, PPH, PVC, PTFE or PVDF. The electrode tips are made of stainless steel 1.4571, Hastelloy B, Hastelloy C, titanium, tantalum or glassy carbon. In this way, the EP can also be used in connection with highly aggressive media.

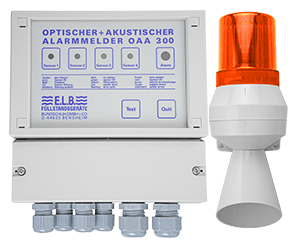

Below you can find an example of a system equipped with the optical and acoustic alarm indicator OAA-300. In total, 4 probes, installed in 2 tanks, are connected to the alarm indicator.

The OAA-300 detects the signals of the connected level sensors / leakage probes and triggers an acoustic signal (acknowledgeable) and an optical signal (not acknowledgeable).

In addition, the signal lines are monitored for line breaks / line short circuits.

The"TEST" function helps you check all connected level sensors / probes for proper function.

The "QUIT" function acknowledges the alarm on site.

The LEDs indicate the status of each level detector / probe, ensuring optimum monitoring:

- Green: Normal operation / alarm acknowledged / sensor OK

- Yellow: Overflow / leakage alarm

- Red: Line / measurement error

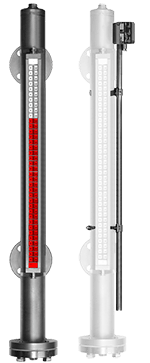

Mechanical level indicator with magnetic flaps for explosive environments

The magnetic flap indicator MKL in combination with the magnetic probe TK307 is an excellent solution for continuous measurement of liquids in hazardous areas (Ex II 1 Gc). Its composition (stainless steel 1.4571 316Ti) makes the MKL very robust and insensitive to corrosive, toxic and highly inflammable media. In addition, the level indicator works completely mechanically and therefore does not require any electrical connection.

- The device can display tank levels up to 6 metres.

According to the principle of communicating vessels, the level in the standpipe is exactly the same as the level in the tank. The float has a special round magnet that rotates 180° around its own axis when the aluminium wafers pass. The red fluorescent colour on its back makes reading off the level very easy.

The continuous, immersible magnetic probe TK307 consists of reed contacts, which are mounted in the guide tube and switched by the magnet of the level indicator MKL. Depending on the filling level, these reed contacts continuously pick up a partial resistance from a chain, consisting of individual resistors.

- The device is also made of stainless steel 1.4571 and can measure levels up to 6 metres.

The digital display AD310 is designed for reading off the analogue signal (4-20mA or 0-10V) in the non-explosive area. It is fully configurable and always displays the required measurement unit (volume, weight, etc. ...). There are two programmable output relays for controlling actuators or sending information to a PLC.

In the following schematic illustration, we will show how it is implemented in practice with the help of an SI barrier, providing galvanic isolation of the signal between the hazardous and protected zone: