- Written by ZILA GmbH

- font size decrease font size increase font size

CO2 detection: Enhanced ripening process of fruit and vegetables through carbon dioxide monitoring

Plants and their fruits are living organisms with a metabolism. They lose water, get sick and can even die. In order to achieve optimum quality from the blossom to the fruit (or vegetable) and finally to the end consumer, it is important to improve the storability and transportability, and thus, to extend their life cycle. A suitable approach for this is the controlled CO2 concentration monitoring.

How can we influence the ripening process?

To begin with, fruits are distinguished into two types. Those that ripen after harvest (climacteric) and those that must be harvested when ripe since their metabolism is practically over (non-climacteric).

Berries, for example, are non-climacteric, as they tend to have a low storage potential. Apples and pears on the contrary can be stored for months and ripen gradually.

To influence and reduce their metabolism, it is necessary to keep the temperature in the storage and transport room at a constantly low level. Other influencing factors include humidity and a low supply of light.

Transmitters and sensors for measuring the temperature and relative humidity

We also offer sensors and transmitters for temperature and humidity measurement.

More information can be found here:

Site map: Temperature and humidity transmitters

In addition, the atmosphere (air composition) where fruits are stored can be changed (so called 'controlled and modified atmosphere'). This is called a controlled and modified atmosphere. By adding CO2 (carbon dioxide), the air mixture is changed so that less oxygen is available for metabolism. Therefore, it is a good idea to monitor and control the CO2 concentration constantly.

However, caution is required when handling CO2. As the gas is colour- and odourless, humans cannot detect the CO2 level. This means that leakages can lead to an uncontrolled, increased CO2 concentration, and thus, can cause damage both to humans and plants.

Knowing about the positive effects of an increased CO2 concentration is very advantageous because

- the quality of your products increases,

- food stays fresh for longer,

- personal injuries are avoided,

- handling with CO2 is safer,

- the dry ice production can be controlled more accurately,

- the cold chain can be maintained and

- you will create the right atmosphere!

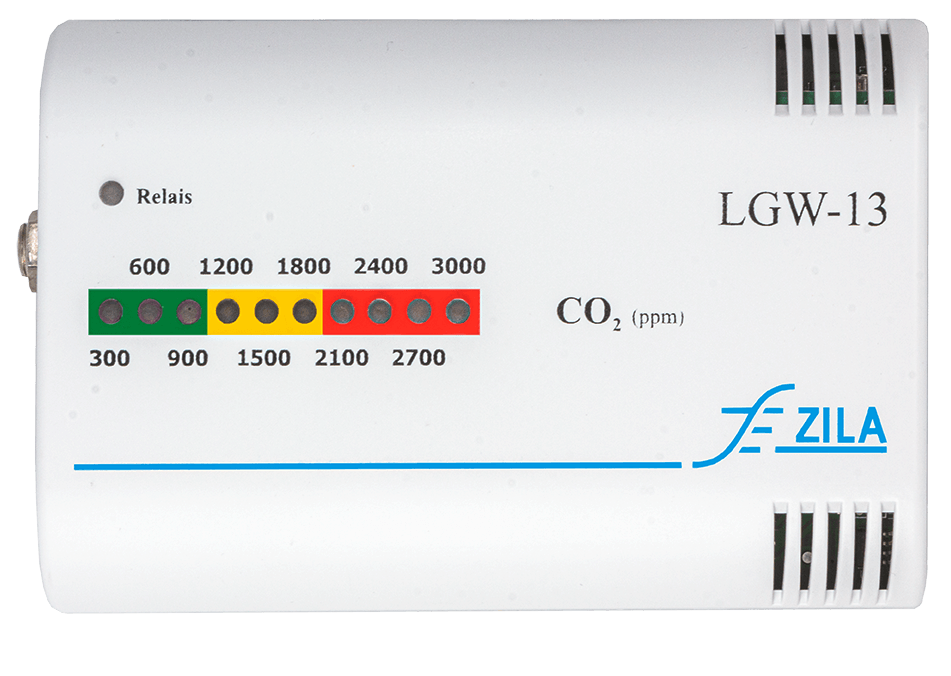

CO2 sensors and detectors

Our various CO2 detectors, suitable for constant CO2 concentration measurement and monitoring, are equipped with precise CO2 sensors in wide measuring ranges.

Carbon dioxide air quality guard with switching function and warning signal transmitter

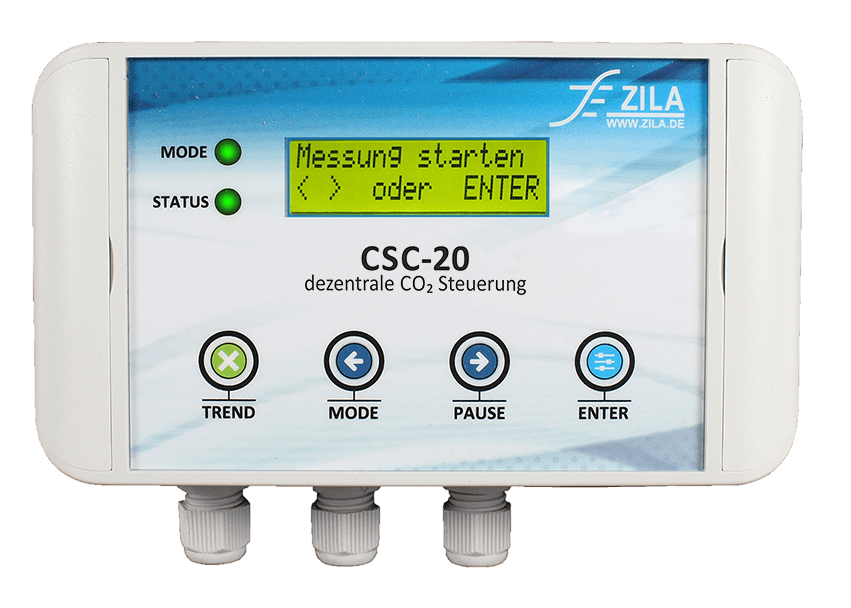

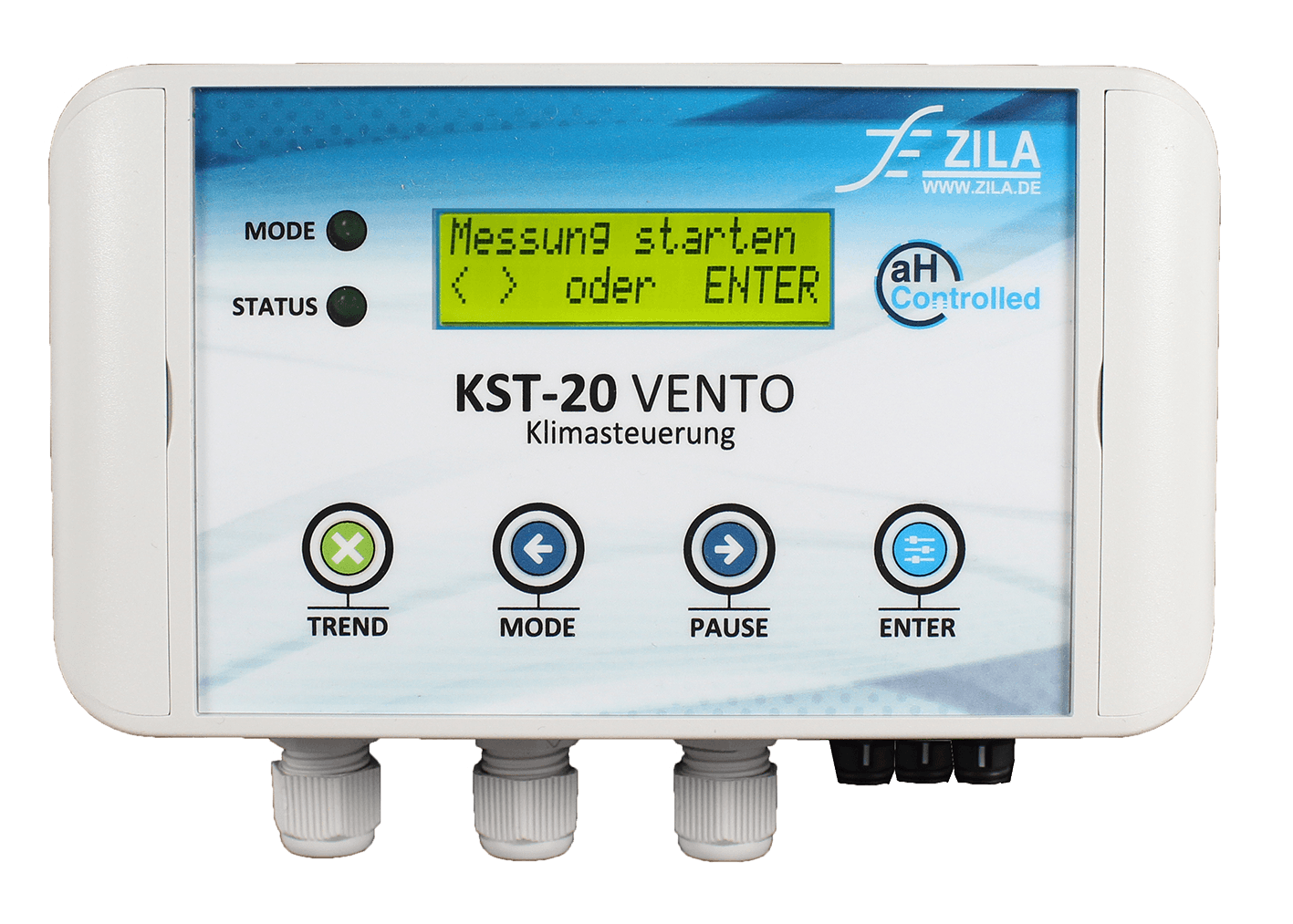

Climate control KST-20 Vento/CO2

Climate control for automatic air quality measurement and room dehumidification

Industrial CO2 sensor ZMF-100-IR

Robust carbon dioxide sensor for industrial applications with optical measuring principle NDIR

More information

Site map: Gas detection